Inert Technology

Inert PureSolv MD7 Solvent Purification System 5 Channels

Inert PureSolv MD7 Solvent Purification System 5 Channels

Couldn't load pickup availability

|

Premium Pre-owned |

|

60-Day Warranty |

|

30-Day Return |

SKU #: XBHU01E1

Inert’s unique dispensing system allows for easy access to anhydrous solvent by multiple users. Our multi-way valve design is considered the most efficient and safest dispensing system on the market today.

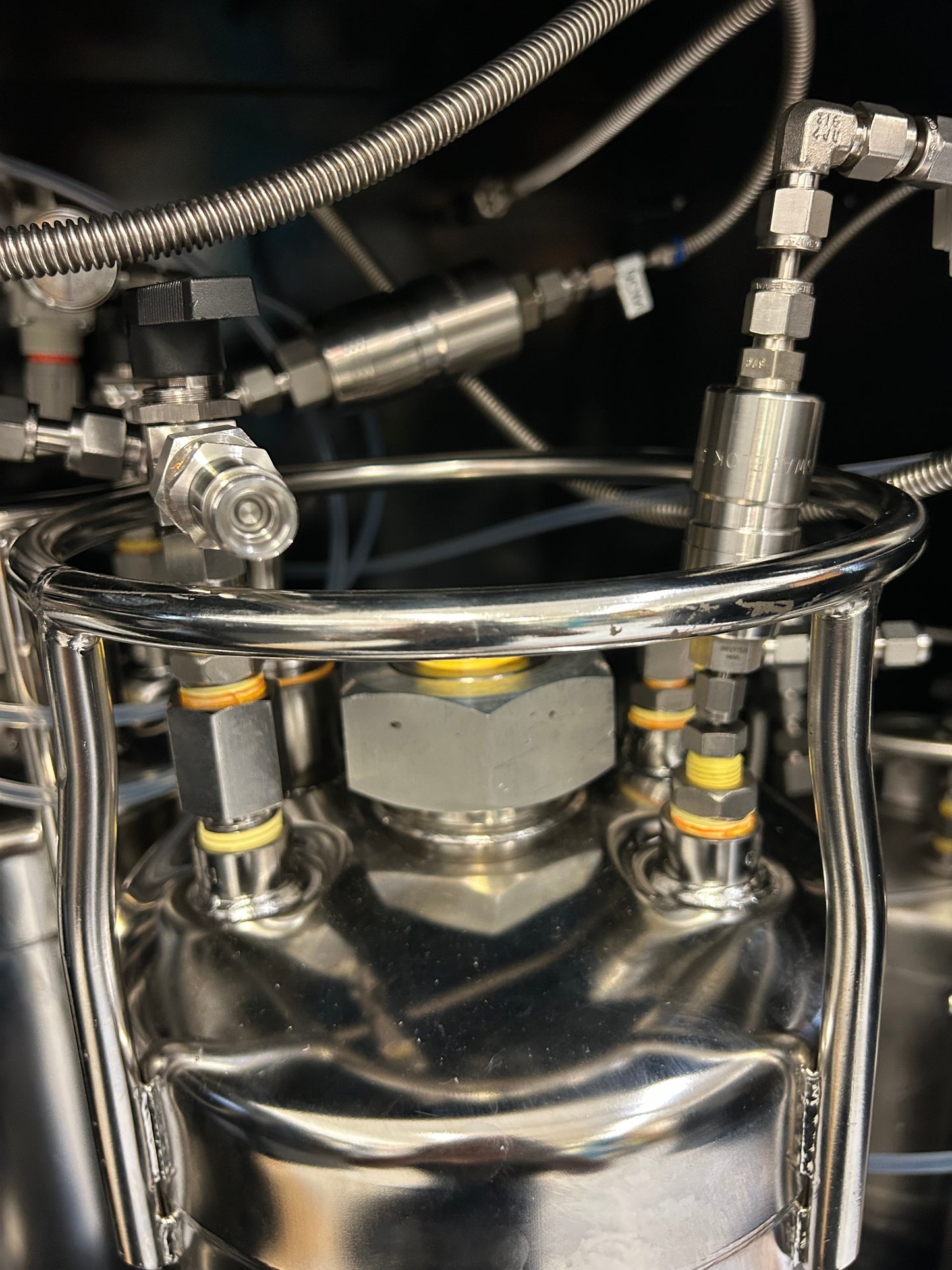

The PureSolv MD dispensing system facilitates proper air-free dispensing techniques using our integrated manifold system.

The PureSolv MD includes customer’s choice of 24/40, 14/20, 29/32 stainless steel glassware adaptors as standard. Other types of connections such as Luer lock needle valves, ball joints, quick disconnect glass adaptors for added flexibility are available upon request.

The PureSolv MD allows for multiple users to operate an air-free dispensing system simultaneously without any risk of cross diffusion of solvent.

Large capacity 5 gallon reservoirs include custom designed, leak tight screw cap and Swagelok quick disconnect valves for easy handling and refilling.

PureSolv MD is bonded and grounded to remove hazards associated with electro static discharge and ensure a safe operating environment. This includes a retractable grounding clamp that connects directly to the solvent reservoir during the refill process.

The PureSolv MD Solvent Purification System can purify up to 800 liters of solvent before column replacement or regeneration is necessary.

Available in free-standing, bench top or wall mounted models. These systems can be designed to mount on top of flammable storage cabinets, as well as inside existing or new fume hoods.

Technical Notes

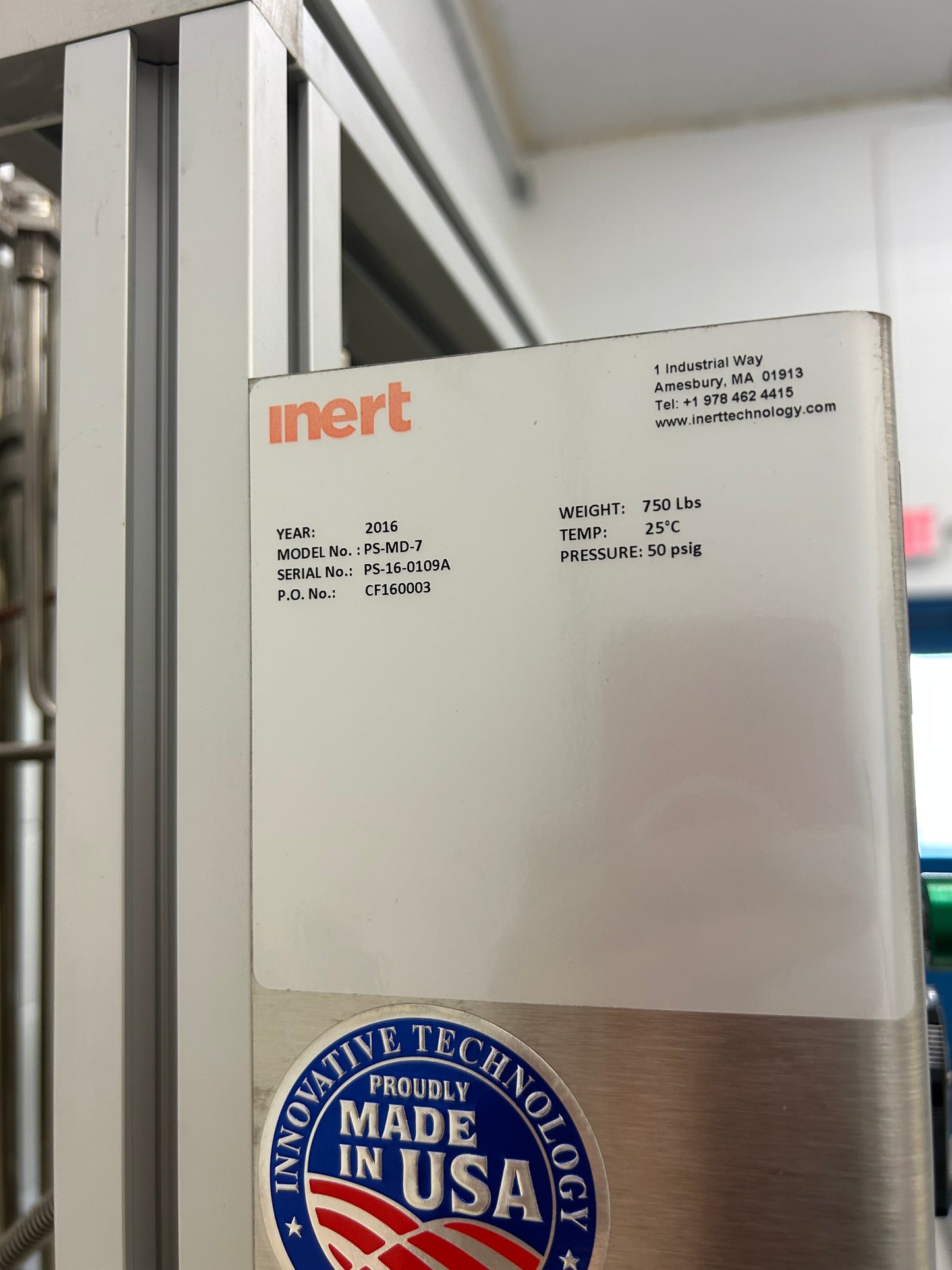

Year of Manufacturing: 2016

The system has been completely cleaned by ALS technicians. All the absorbents were removed from the purification column. The labels indicate the solvents previously used in the channels. However, since the system has been thoroughly cleaned, you can use any solvents in any channel.

The OEM solvent kegs were missing. Solvent kegs from Alloy Products will be supplied with all necessary fittings and connections installed. Note that these kegs are superior to the OEM kegs, which are basically repurposed beer kegs. All fittings were leak-tested with leak-detection fluid. The entire system was pressurized to 25 PSI to ensure there were no leaks. The functions of all valves and gauges were checked and confirmed.

Defects

No defects observedIncluded with the purchase

- MD7 Solvent Purification System with 5 channels and 10 columns in total (absorbent removed)

- Three 5-gallon and two 3-gallon solvent kegs

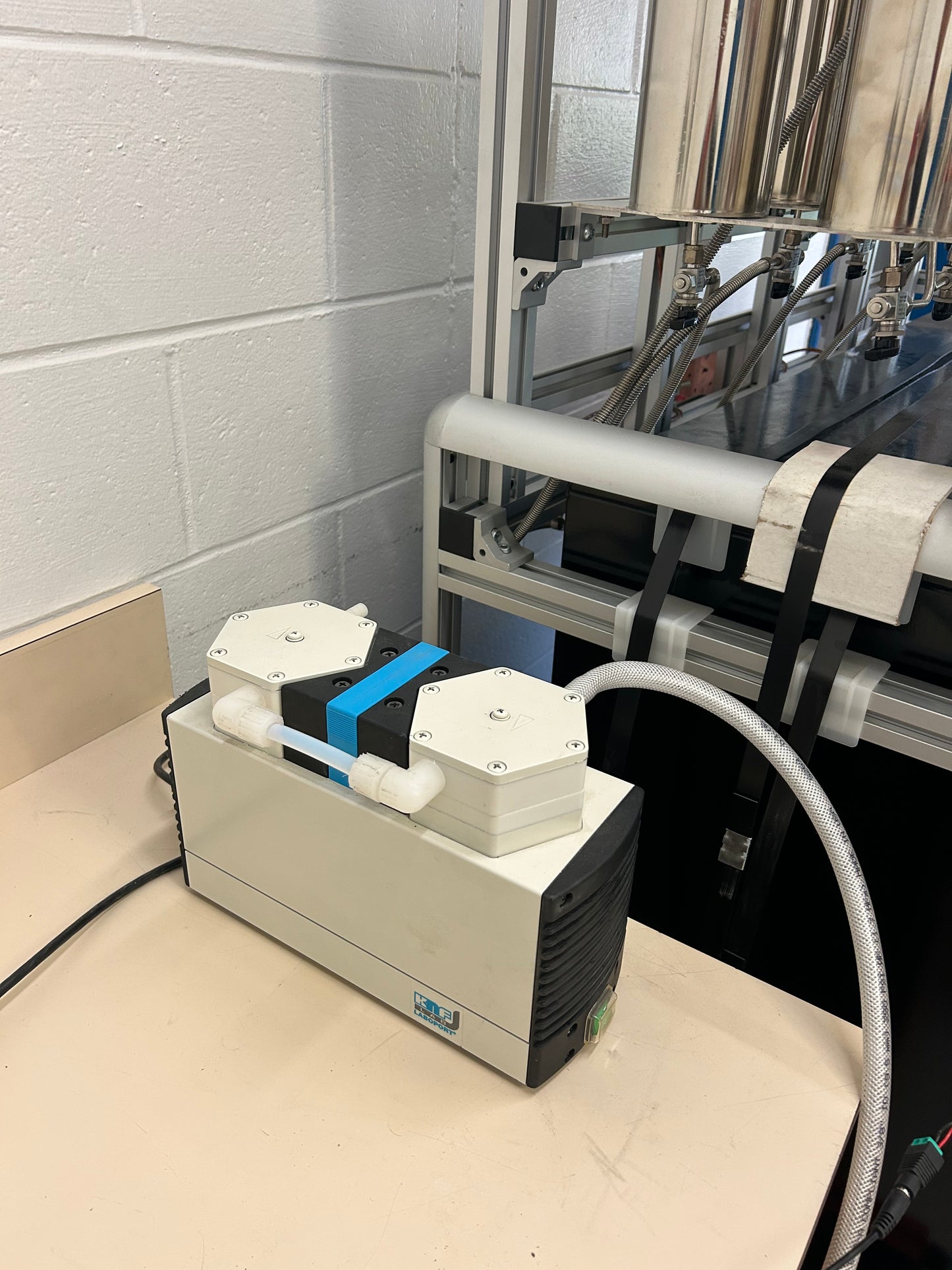

- A KNF Labport vacuum pump

- 60-Day Warranty

Share